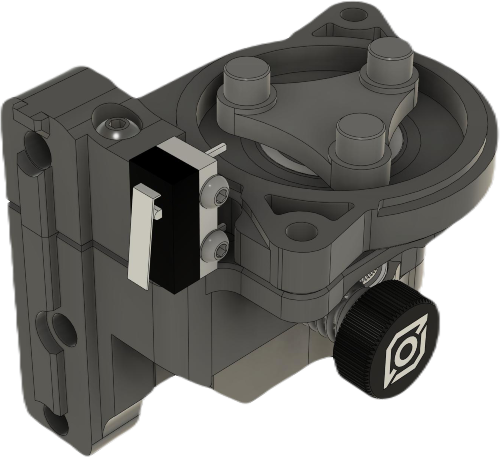

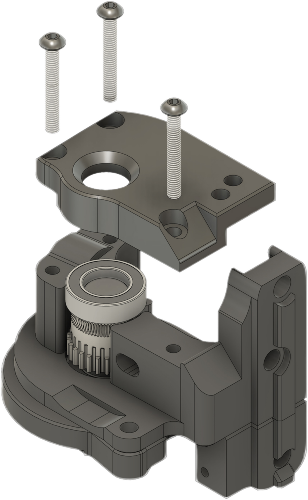

¶ Extruder Assembly Guide

This guide is for extruder hardware kit that was shipped with the Positron v3.2.0 and v3.2.1 (Batch 1 and 2)

¶ Required Parts

¶ Hardware

Many of these parts will be in a bag labeled Extruder Kit

- Bearing, MF148ZZ

- Machine Screw, BHCS, M3x25

- M3x3 Set Screw

- Spider Shaft

- Primary Gear

- Bushing, POM, 8x4x11

- Idler Gear, Orbiter 2

- Shaft, 4x16

- Thumbscrew, M3x30

- Spring, 1x5.9x11.3mm

- Bearing, MR148ZZ

- ECAS04 Bowden Coupler

- Shim Washer, 3x6x0.5mm

- Heat set Insert, Brass, M3x6x5

- 3x Heat set Insert, Brass, M2.5x3x4

- 4x Machine Screw, BHCS, M2.5x18

- 2x Self-tapping Screw, M2x10

- Z Endstop Micro Switch and Cable

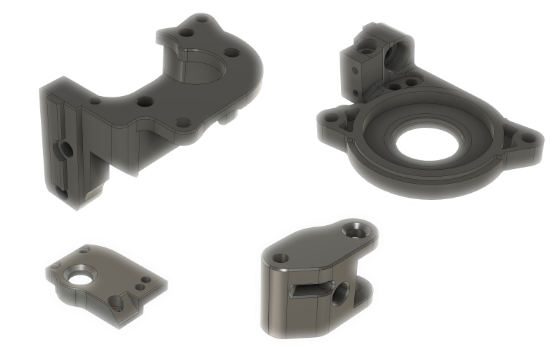

¶ Printed Parts

List of printed parts for the extruder assembly

- Extruder Main Body

- Extruder Motor Plate

- Extruder Bottom Plate

- Extruder Guidler

STL models can be found on the Positron Printed Parts Github

Models have not been scaled to account for material shrinkage

¶ Assemble

¶ Prepare the Printed Parts

Install heat set inserts into the printed parts

Parts Needed:

- 1x Heat set Insert, Brass, M3x6x5

- 3x Heat set Insert, Brass, M2.5x3x4

- Extruder Guidler

- Extruder Main Body

¶ Guilder

- Install the M3x6x5 heat set insert into the printed guidler.

¶ Extruder Main Body

Batch 1 Extruder Main Body did not use heat set insert but had screws that threaded directly into the printed part.

- Install all three M2.5x3x4 heat set inserts into the printed extruder main body.

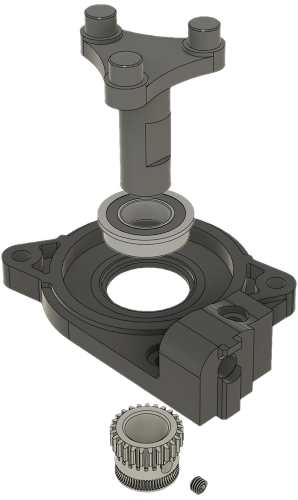

¶ Motor Plate and Planetary Gear Shaft

For all the M2.5 screws, please use the included LDO screwdriver.

Parts Needed:

- 1x Bearing, MF148ZZ

- 1x M3x3 Set Screw

- 1x Spider Shaft

- 1x Primary Gear

- 1x Bearing, MR148ZZ

- Extruder Motor Plate

¶ Install CNC Shaft

- Place the MF148ZZ bearing into the hole of the Extruder Motor Plate and be sure it sits

flush or below the surface of the part.

- Insert the Spider Shaft through the opening of the MG148ZZ bearing.

¶ Install Primary Gear

- Slide the Primary Gear onto the Spider Shaft.

- Line up the hole in the Gear with the flat spot on the Spider Shaft.

- Screw in the Set Screw through the gear and stop right before it touches the flat spot.

- Now slide the gear all the way down the Spider Shaft until the Set Screw hits the end of the flat spot.

- Tightened down the Set Screw until the gear doesn't move, the height of the gear will be adjusted later.

- Place the MR148ZZ bearing on the end of the shaft and get ready for the next step.

¶ Install Lower Half

Parts Needed:

- 3x Machine Screw, BHCS, M2.5x18

- Assembled Extruder Motor Plate

- Extruder Main Body

- Extruder Bottom Plate

¶ Main Extruder Body

- Combine the Extruder Motor Plate and Extruder Main Body.

- Flip over for next step.

¶ Install Extruder Bottom Plate

- Cover the Extruder Main Body with the Extruder Bottom Plate and press it flat. If it does not

sit flat press the MR148ZZ bearing into the Extruder Bottom Plate first. - Secure Extruder Bottom Plate with three M2.5x18 BHCS Screws

Batch 1 uses three M2.5x10 BHCS Screws and only taps into printed part.

¶ Prepare the Extruder Guidler

Parts Needed:

- 1x Bushing, POM, 8x4x11

- 1x Idler Gear, Orbiter 2

- 1x Shaft, 4x16

- Extruder Guidler

- Place the bushing into Idler Gear.

- Rotate Extruder Guidler so larger opening is facing up.

- Position the Idler Gear (Gear teeth side down) into the opening of the Extruder Guidler and secure with the 4x16 Shaft (Smooth end first)

- The 4x16 Shaft has knurling on one end. Press fit the Shaft into the Extruder Guidler until it is flush and holds the Idler Gear in place.

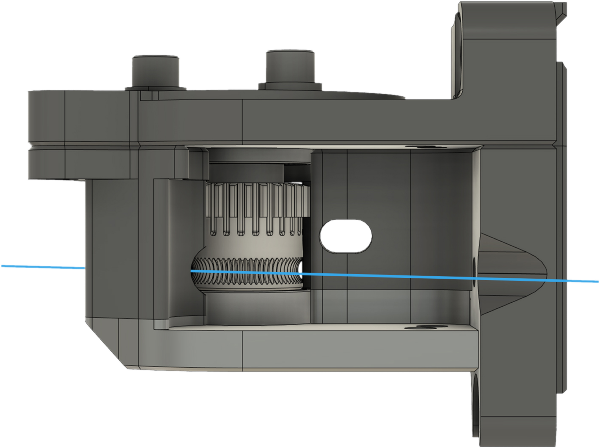

¶ Check Filament Path

Parts Needed:

- Piece of filament longer than the extruder

- Assembled Extruder Body

- First loosen the M3x3 Set Screw so the Primary Gear can slide up and down.

- Insert a piece of filament as shown in above photo.

- Align the Primary Gear so the filament teeth are centered on the filament and the exit path for filament, and tighten down the M3x3 Set Screw.

¶ Install the Extruder Guidler

Part Needed:

- 1x Machine Screw, BHCS, M3x25

- 1x Machine Screw, BHCS, M2.5x18

- Assembled Extruder Main Body

- Extruder Guidler

¶ Secure Guilder

- Position the Extruder Guidler with gear teeth side up and into the Extruder Main Body.

- Secure with a M3x25 BHCS Screw. The screw taps into the Extruder Bottom plate.

¶ Anchor Motor Plate

- Secure Extruder Motor Plate with a M2.5x18 BHCS Screw. Screw taps directly into the printed parts.

¶ Install the Bowden Coupler

Parts Needed:

- 1x ECAS04 Bowden Coupler

- Assembled Extruder Body

- Remove any rubber from the Bowden Coupler

- Install the Bowden Coupler into the extruder. The Bowden Coupler flange should be flush with the Extruder Body.

¶ Install the Thumbscrew

Parts Needed:

- 1x Thumbscrew, M3x30

- 1x Spring, 1x5.9x11.3mm

- 1x Shim Washer, 3x6x0.5mm

- Assembled Extruder Body

- While holding the Thumbscrew, drop the Spring onto the bolt end followed by the Shim Washer.

- Insert Thumbscrew from opposite side of the Guidler and thread into the Heat Set insert until Thumbscrew head is flush with the printed part above it.

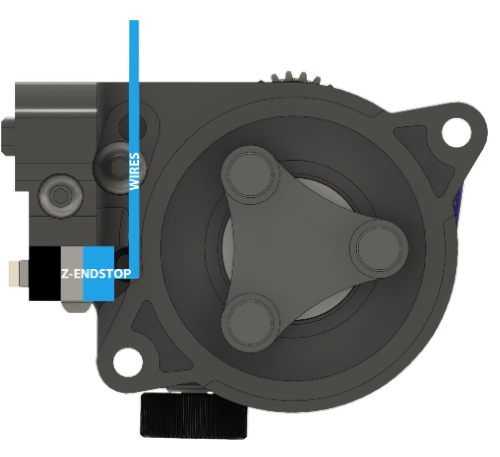

¶ Install the Endstop

Parts Needed:

- 2x Self-tapping Screw, M2x10

- 1x Z Endstop Micro Switch and Cable

- Assembled Extruder Body

- Using the photo above prebend the wires on the Z Endstop with the lever facing down, in preparation to mount it.

- Secure the endstop to the printed part using two M2x10 Self-taping screws.

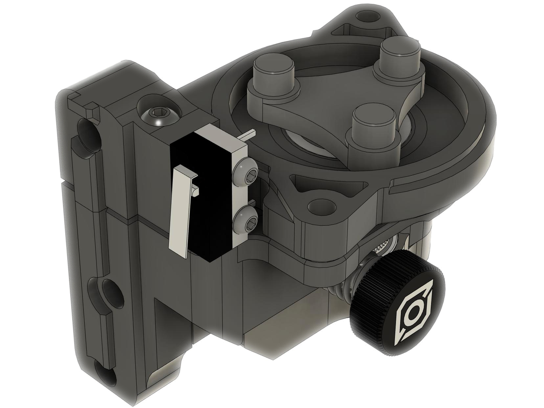

¶ Extruder Complete

- Congratulations the extruder is complete, the motor will be mounted towards the end of the Positron v3.2 assembly.